Author: Site Editor Publish Time: 2026-01-28 Origin: Site

Honeycomb core materials are an essential part of modern manufacturing, offering high strength-to-weight ratios. These materials play a key role in industries like aerospace, automotive, marine, and construction, where strength and durability are crucial. By integrating honeycomb cores into sandwich panels, manufacturers create robust yet lightweight structures that perform excellently under pressure.

In this article, we will explore the different types of honeycomb core materials and their applications. You will learn how these materials are revolutionizing industries and how Shenxi Honeycomb has contributed to this field with over 30 projects in 27 countries.

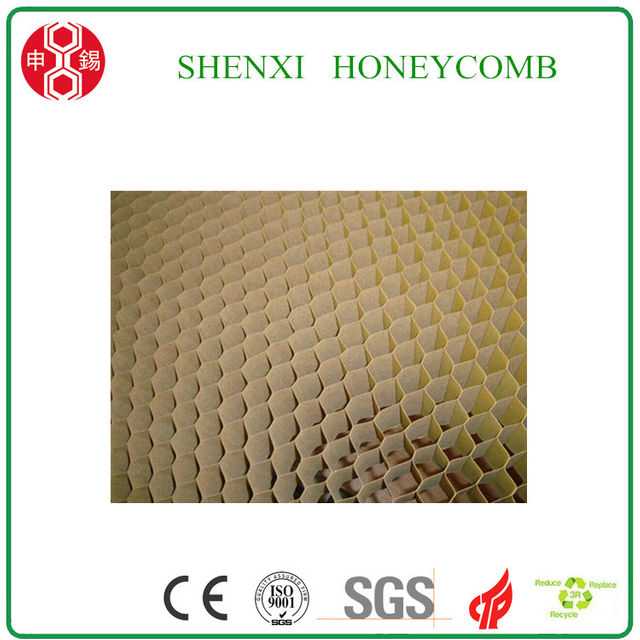

Honeycomb core materials feature a unique hexagonal design that mimics natural honeycombs. This structure offers high strength while minimizing material usage, making it ideal for lightweight, durable components. The honeycomb design efficiently distributes stresses, ensuring stability and performance under pressure. It is widely used in industries like aerospace, automotive, and construction.

Property | Detail | Application |

Hexagonal Structure | Mimics natural honeycombs, maximizing strength. | Aerospace, automotive, construction |

Strength-to-Weight Ratio | High strength with minimal material. | Aircraft, vehicles, machinery |

Stress Distribution | Even stress distribution across the surface. | Structural panels, vehicle parts |

Lightweight | Minimal material for reduced weight. | Aircraft interiors, vehicle panels |

Honeycomb cores are commonly used in sandwich panels, which consist of two outer layers (called face sheets) with the honeycomb core placed in between. This structure is widely utilized across various sectors, including aerospace, automotive, marine, and construction. The honeycomb core adds rigidity and strength to the panels, making them suitable for demanding environments such as aircraft wings, car body panels, and ship hulls.

These panels are engineered for applications where weight reduction is just as important as performance, offering an ideal solution for structures that need to be both strong and lightweight. Shenxi Honeycomb is known for offering customized honeycomb core materials designed to meet the specific needs of different industries, ensuring that their clients receive optimal solutions for their applications.

Honeycomb core materials have gained popularity due to their numerous benefits, including:

● High Rigidity: The core's design allows it to resist deformation under stress, making it ideal for structural applications.

● Energy Absorption: The hexagonal design absorbs energy during impacts, making it ideal for applications where safety and durability are priorities.

● Acoustic Insulation: The empty spaces in the honeycomb core provide excellent sound insulation, making it a popular choice for noise-sensitive environments.

● Recyclability: Many honeycomb core materials are recyclable, which aligns with the growing demand for sustainable materials.

● Tailorable Performance: The strength, stiffness, and energy absorption properties of honeycomb cores can be customized based on the material, cell size, and configuration, allowing for targeted performance optimization.

Honeycomb cores come in various materials, each offering distinct advantages based on their properties. Here's an overview of the most common types:

Properties:

Aluminum honeycomb cores are known for their exceptional strength-to-weight ratio. They also offer excellent corrosion resistance and can withstand high temperatures, making them ideal for aerospace applications.

Applications:

These cores are commonly used in aerospace, automotive, marine, and industrial applications, where strength and durability are crucial. Aircraft interiors, floors, and structural components often use aluminum honeycomb cores for their light weight and strength.Aluminum honeycomb cores are particularly favored for their durability in harsh environments, where components face extreme temperature fluctuations and high-stress conditions.

Properties:

Aramid honeycomb cores are fire-resistant, fatigue-resistant, and offer superior heat resistance. This makes them particularly suitable for environments where high temperatures or fire hazards are a concern.

Applications:

They are commonly used in aerospace interiors, helicopter rotors, and railway systems, where fire safety and high-performance characteristics are vital. Aramid honeycomb cores are a preferred choice for any application where fire retardancy and lightweight characteristics are crucial, particularly in high-performance industries like aerospace.

Properties:

Thermoplastic honeycomb cores are lightweight, chemical- and water-resistant, and highly recyclable. These materials can easily be molded, making them versatile for a variety of applications.

Applications:

Thermoplastic cores are used in the marine industry for boat hulls, automotive parts for reducing vehicle weight, and construction applications such as lightweight panels.These cores are also popular in applications where flexibility and recyclability are important, particularly in industries looking to reduce environmental impact.

Properties:

Fiberglass honeycomb cores combine glass fibers with resins to provide a balance of strength, durability, and corrosion resistance. These cores are also electrically insulating, making them ideal for specific industrial applications.

Applications:

Fiberglass cores are often used in marine environments, electrical insulation applications, and specialty industrial products.Fiberglass honeycomb cores are particularly valuable for industries that require both corrosion resistance and the ability to withstand harsh environmental conditions, such as saltwater exposure in the marine industry.

Properties:

Paper honeycomb cores are inexpensive, lightweight, and recyclable. They are commonly used for non-structural, low-load applications.

Applications:

These cores are typically found in packaging, furniture, and logistics, where weight reduction and cost efficiency are important.Paper honeycomb cores are a cost-effective solution for applications that do not require high strength but still benefit from the material's lightweight nature.

Material | Properties | Applications |

Aluminum | High strength-to-weight ratio, corrosion resistance, heat resistance | Aerospace, automotive, marine, industrial |

Aramid | Fire-resistant, heat-resistant, fatigue-resistant | Aerospace interiors, helicopters, railways |

Thermoplastic | Lightweight, chemical and water-resistant, recyclable | Marine vessels, automotive, construction |

Fiberglass | Durable, corrosion-resistant, electrically insulating | Marine, electrical insulation, industrial |

Paper | Lightweight, recyclable, low-cost | Packaging, furniture, logistics |

The most significant advantage of honeycomb core materials is their excellent strength-to-weight ratio. The hexagonal structure provides high strength while minimizing the overall weight of the component. This makes honeycomb cores ideal for applications in industries where reducing weight is crucial, such as aerospace and automotive.

The design of honeycomb cores ensures that they can withstand substantial loads while remaining lightweight, which makes them indispensable in applications where performance and weight are critical.

Honeycomb cores are highly effective at absorbing energy during impact, making them a popular choice for applications requiring crash protection or energy dissipation. The design allows the material to deform in a controlled manner, dissipating impact forces and reducing the risk of damage.

This property is particularly important in industries like automotive and aerospace, where safety and impact resistance are key concerns.

The hollow pockets within the honeycomb core provide excellent insulation properties. These cores are highly effective at blocking sound and reducing heat transfer, making them suitable for environments that require soundproofing or temperature control.

Honeycomb cores are increasingly used in applications where maintaining optimal temperature or minimizing noise levels is a top priority, such as in construction and high-tech industrial equipment.

Honeycomb core materials are engineered to withstand various environmental factors, including chemical exposure, moisture, and extreme temperatures. Different materials, such as aluminum, fiberglass, and thermoplastics, offer varying levels of resistance depending on the application.

By selecting the appropriate material, businesses can ensure the longevity and reliability of their products even in harsh conditions.

Property | Description |

Strength-to-Weight Ratio | High strength with minimal weight. |

Energy Absorption | Absorbs impact energy, reducing damage. |

Acoustic & Thermal Insulation | Blocks sound and reduces heat transfer. |

Durability & Environmental Resistance | Withstands chemicals, moisture, and extreme temperatures. |

The process of creating honeycomb cores starts with selecting the appropriate material for the intended application. Factors such as load requirements, environmental conditions, and desired performance characteristics play a crucial role in this decision.

This initial step ensures that the final product will meet the specific demands of the industry and its operational environment.

Once the material is chosen, it is processed into sheets or strips. For metals like aluminum, the sheets are often treated to improve properties like corrosion resistance. These sheets are then stacked and bonded together before being pulled through a die to form the signature hexagonal cells.

The core formation process allows manufacturers to adjust the density and size of the cells, tailoring the material’s properties to suit specific applications.

After the honeycomb structure is created, it is cut to the required size and shaped according to the application. Finishing processes, such as anodizing for aluminum cores or applying flame-retardant coatings for Nomex, enhance the material's performance in specific environments.

Advanced cutting techniques ensure that the honeycomb core fits precisely into the intended design, improving the efficiency and structural integrity of the final product.

Honeycomb core materials are widely used in the aerospace industry, where strength and lightweight properties are essential. Components like floors, structural parts, and interiors in aircraft rely on honeycomb cores for their rigidity and performance.

Shenxi Honeycomb is a key supplier of aerospace-grade honeycomb cores, providing materials used in critical components such as aircraft flooring and interior panels.

These materials help reduce the overall weight of aircraft while maintaining the strength and performance required in demanding aerospace environments.

Honeycomb cores are also used extensively in the marine industry. The lightweight yet durable properties of honeycomb cores make them ideal for boat hulls, yachts, and military vessels. These cores help reduce the weight of the structure while maintaining strength, crucial for vessel performance.

In the automotive industry, honeycomb cores are used to reduce vehicle weight and improve fuel efficiency. Applications include energy-absorbing bumpers, lightweight body panels, and interior components, which contribute to overall vehicle performance.

The demand for lightweight materials in the automotive sector is growing as manufacturers work to meet stricter fuel efficiency regulations and sustainability goals.

Honeycomb core materials are commonly used in facade cladding, roofing, and partition walls, particularly in cleanroom applications. The material’s rigidity and insulation properties make it ideal for creating durable, lightweight building components.

Honeycomb cores provide a sustainable option for architects and builders looking to incorporate energy-efficient and durable materials into their designs.

Honeycomb cores are also found in various industrial applications, including sporting goods, loudspeakers, and LED technology. The versatility of honeycomb core materials ensures their use across a wide range of industries.

Industry | Applications | Key Benefits |

Aerospace | Aircraft floors, structural parts, interiors | Lightweight, high strength, performance |

Marine | Boat hulls, yachts, military vessels | Reduces weight, maintains vessel strength |

Automotive | Bumpers, body panels, interior components | Reduces weight, improves fuel efficiency |

Construction & Architecture | Facade cladding, roofing, cleanroom panels | Durability, insulation, energy efficiency |

Industrial & Other | Sporting goods, loudspeakers, LED technology | Versatility, performance in various sectors |

When selecting a honeycomb core material, it is crucial to assess the load requirements. For high-load applications, materials like aluminum or fiberglass are ideal due to their strength and durability. For low-load applications, lighter materials such as paper or thermoplastic cores may be more suitable.

Consider the environmental conditions the honeycomb core will be exposed to. For high-temperature or fire-resistant needs, Nomex or fiberglass are excellent choices. For marine or humid environments, thermoplastic materials offer superior resistance to water and corrosion.

Balancing cost with performance is always a key factor. Shenxi Honeycomb provides a range of honeycomb core materials that cater to various budgets, without compromising on performance. Additionally, many of these materials are recyclable, supporting sustainability goals.

The choice of material also impacts the long-term environmental footprint of the final product, making sustainability a key consideration for many industries.

Honeycomb core materials offer a unique blend of strength, durability, and lightweight properties, making them vital across many industries. From aerospace to construction, these materials are essential where performance and weight reduction matter most. Shenxi Honeycomb, with years of experience and a global presence, remains a trusted partner for businesses seeking high-quality honeycomb core materials. Whether enhancing energy absorption, improving environmental resistance, or reducing weight, Shenxi Honeycomb provides tailored solutions to meet diverse needs.

A: Honeycomb core materials are lightweight, high-strength structures used in sandwich panels. They provide exceptional strength-to-weight ratios, making them ideal for aerospace, automotive, and construction industries.

A: Honeycomb core materials are used in aerospace for components like floors, wings, and interior panels. Their light weight and durability improve fuel efficiency and performance while ensuring safety.

A: Honeycomb core materials are popular because they offer a unique combination of strength, durability, and lightness. They excel in weight-sensitive applications across industries like aerospace, automotive, and marine.

A: The main types of honeycomb core materials include aluminum, aramid, thermoplastic, fiberglass, and paper. Each type has unique properties suited for specific applications, such as heat resistance or recyclability.

A: Honeycomb core materials absorb impact energy by deforming in a controlled manner, thanks to their hexagonal structure. This makes them ideal for safety applications in vehicles and aerospace structures.

A: Shenxi Honeycomb is known for its high-quality, customized honeycomb core materials that offer superior performance, weight reduction, and durability. Their extensive experience makes them a trusted partner in various industries.