Author: Site Editor Publish Time: 2025-07-15 Origin: Site

Have you ever wondered how lightweight materials can provide both strength and sustainability? Honeycomb paperboard, also known as Hexacomb, is a versatile material that meets these demands. Known for its strength, eco-friendliness, and lightweight nature, it’s widely used in packaging, construction, automotive, and more. In this post, we’ll explore the various uses of honeycomb paperboard and how it benefits different industries.

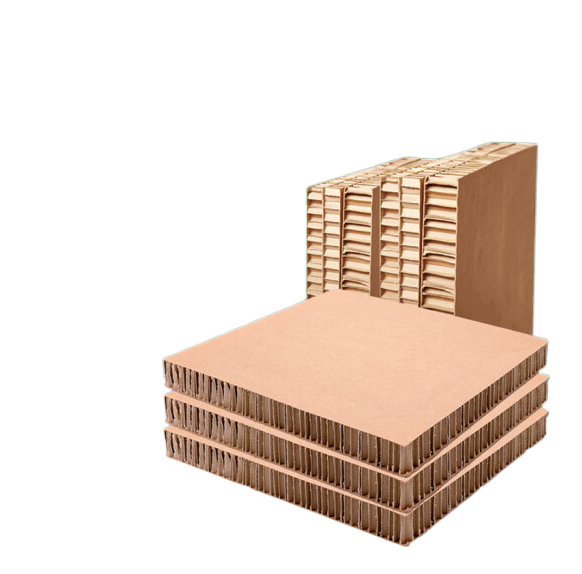

Honeycomb paperboard, also known as honeycomb cardboard, is made from recycled paper. It features a unique hexagonal core structure, which is sandwiched between two layers of paper. This design provides impressive strength despite being lightweight. The material is not only eco-friendly but also offers great shock absorption, making it ideal for protecting fragile items.

The process of making honeycomb paperboard starts with recycled paper. Organic adhesives are used to bond the layers together. Once the layers are bonded, the paper is shaped into the distinctive hexagonal core pattern. This core structure is key to its strength and durability. Afterward, the material is cut and shaped to fit specific applications, whether for packaging or construction.

Protection and Stabilization

Honeycomb paperboard is widely used in packaging to stabilize goods during transit. The unique hexagonal core structure provides excellent shock absorption, effectively protecting fragile items from damage caused by impacts, vibrations, and shocks. This makes it an ideal material for packaging delicate items like glassware, electronics, and artwork, ensuring they remain intact during transportation. The material's durability also helps prevent wear and tear on products, making it a reliable choice for high-value shipments.

Custom Shapes for Packaging

One of the standout features of honeycomb paperboard is its flexibility. It can be easily cut and customized to suit various products, including irregular shapes. Whether you're packing delicate, oddly shaped glassware or large, bulky industrial components, honeycomb paperboard can be tailored to meet specific requirements. This customization ensures that each product is protected while minimizing excess material usage, making it an efficient and cost-effective choice for diverse packaging needs.

Void Filling in Packaging

Honeycomb paperboard excels at void filling in packaging. When used in box packaging, it fills empty spaces that might otherwise allow products to shift. This ensures that items remain securely in place throughout the shipping process. The core's shock-absorbing properties provide extra cushioning and support, preventing damage to fragile items from movement or impact. This extra protection is particularly important for items that require a higher level of care, such as electronics or fragile machinery.

Pallet Stabilization

Beyond individual product protection, honeycomb paperboard plays a critical role in pallet stabilization. When used to reinforce pallets, it prevents shifting loads during transport. Honeycomb paperboard is strong enough to hold large quantities of goods in place, minimizing the risk of damage or loss during shipping. By stabilizing the load, it reduces the likelihood of product displacement or structural collapse, ensuring safer and more reliable shipments. Additionally, honeycomb paperboard is lightweight, so it won’t add significant weight to the load, helping to keep shipping costs down.

Lightweight Panels

Honeycomb paperboard is commonly used to create lightweight panels for walls, ceilings, and floors in construction. These panels offer a significant reduction in weight compared to traditional materials such as wood, steel, or concrete. This weight reduction provides several advantages, including easier handling, faster installation, and reduced transportation costs. It also helps improve the overall efficiency of the construction process, making it ideal for modern building projects that prioritize both strength and ease of use. The lightweight nature of the panels also makes them easier to maneuver, reducing the need for heavy lifting equipment.

Temporary Partitions and Structural Support

Honeycomb paperboard is an excellent choice for creating temporary partitions in construction projects. Whether it’s for offices, exhibition booths, or other temporary setups, the material offers a flexible and cost-effective solution. Its strength and ability to be cut into various sizes allow for the creation of movable walls that can easily be assembled and disassembled as needed. Additionally, honeycomb paperboard is used as a core material in composite panels, providing structural support without adding unnecessary weight. This makes it perfect for applications where lightweight, movable, and cost-efficient partitioning is needed.

Ground Heave Protection

In areas prone to ground movement, honeycomb paperboard plays an essential role in mitigating ground heave. By creating expansion voids beneath buildings, it helps prevent ground movement from damaging foundations. This is particularly useful in regions where soil expansion and contraction are common due to changes in moisture levels or temperature. Honeycomb paperboard provides a flexible yet durable solution for protecting foundations, helping to prevent costly structural damage in the long term.

Enhanced Durability in Construction

Despite its lightweight design, honeycomb paperboard is highly durable and able to withstand environmental stresses such as moisture, temperature fluctuations, and physical wear. This durability makes it suitable for both indoor and outdoor construction applications. Whether used in exterior panels or interior partitioning, honeycomb paperboard can handle the challenges of different environments, ensuring long-lasting performance and reducing the need for frequent replacements.

Furniture Manufacturing

Honeycomb paperboard is used as a core material in furniture, reducing overall weight while maintaining strength. It’s perfect for making lighter furniture without sacrificing durability. This makes it easier to transport and handle, especially in large pieces like tables, cabinets, and chairs.

Automotive Industry

In the automotive industry, honeycomb paperboard is crucial for packaging and transporting automotive parts. Its lightweight and shock-absorbing properties reduce shipping costs and improve fuel efficiency. By protecting parts during transport, it ensures that they arrive in perfect condition.

Signage and Exhibition Displays

Honeycomb paperboard is often the material of choice for signs and point-of-sale displays. Its excellent printability and ability to be easily shaped make it ideal for creating eye-catching, lightweight displays. This versatility helps create custom displays for retail and exhibition use.

Sustainable Furniture Solutions

Honeycomb paperboard is a key material in creating sustainable furniture solutions. It reduces the weight of furniture, making it easier to handle and move while maintaining structural integrity. Its use in furniture is an environmentally friendly alternative, as it minimizes material waste.

Recycled Material

Honeycomb paperboard is made entirely from 100% recyclable materials. By using recycled paper, it contributes to environmental conservation, reducing the need for virgin resources. This makes it a greener choice compared to traditional packaging materials.

Biodegradable and Non-Toxic

The material is biodegradable and free from harmful toxic substances. Unlike plastic or foam, honeycomb paperboard breaks down naturally, causing minimal environmental impact. It’s a safer, eco-friendly option for industries looking to reduce their ecological footprint.

Energy Efficient Production

The production of honeycomb paperboard uses significantly less energy compared to other materials like plastic or foam. This energy efficiency not only lowers production costs but also reduces carbon emissions, making it a more sustainable choice.

Honeycomb paperboard serves as an eco-friendly alternative to non-sustainable materials such as foam and plastic. By replacing these harmful materials, it helps reduce plastic waste and encourages a circular economy. Its lightweight nature also helps reduce the carbon footprint in transportation and shipping. Less weight means lower fuel consumption during transport, contributing to more sustainable logistics.

Eliminating the Need for Fumigation

Since honeycomb paperboard is sterilized during production, it eliminates the need for fumigation. This not only makes the material more eco-friendly for exports but also reduces chemical usage, further promoting environmental responsibility.

Honeycomb paperboard is known for its impressive strength-to-weight ratio. Despite being lightweight, it is incredibly durable, capable of supporting heavy loads without the bulk. This makes it perfect for applications where strength is required but weight must be minimized.

Comparison to Traditional Materials

When compared to traditional materials like polystyrene foam or wooden boards, honeycomb paperboard outperforms in both strength and sustainability. It provides similar or even better protection while being much lighter and environmentally friendly.

Custom Sizes and Shapes

One of the standout features of honeycomb paperboard is its versatility. It can be easily cut and shaped into custom sizes, making it suitable for a wide range of applications. From packaging to furniture, it can be tailored to meet specific needs.

Adaptability for Different Industries

Honeycomb paperboard's adaptability spans across multiple industries, including automotive, packaging, construction, and furniture. Its ability to be customized and used in different forms makes it an ideal material for diverse projects.

Special Processing for Enhanced Functions

Honeycomb paperboard can be treated to enhance its properties. Special treatments like flame retardancy, water resistance, and mildew prevention make it suitable for even more specialized applications, further broadening its usefulness.

Honeycomb paperboard is a cost-effective material compared to more expensive options like wood or foam. Its affordability, combined with its performance, offers significant savings, especially in bulk packaging and construction.

The lightweight nature of honeycomb paperboard results in long-term savings in transportation. Less weight means reduced fuel costs and lower shipping fees, benefiting businesses that need to transport large quantities.

Durability and Reusability

In addition to being cost-effective, honey

Thickness and Grammage

The thickness and grammage of honeycomb paperboard are key factors in determining its strength and durability. Thicker and heavier boards offer more strength, making them ideal for heavy-duty applications. If you need something lighter, thinner boards might be a better fit while still providing sufficient protection.

Cell Size and Core Structure

The cell size and core structure affect how the paperboard performs. Smaller cells typically offer greater strength, while larger cells provide more cushioning. Consider your specific needs—whether you require strength or cushioning—before selecting the right honeycomb design.

Special Processing for Unique Functions

Honeycomb paperboard can be treated for special functions, such as water resistance, flame retardancy, or mildew resistance. These treatments are essential for specific environments where extra durability is needed, like outdoor use or in construction projects exposed to moisture.

For Heavy Duty Packaging

For heavier loads, choose thicker honeycomb paperboard. It provides the strength needed to protect heavy products during shipping or storage.

For Lightweight Packaging

If your goods are light, thinner panels will be sufficient. They still offer strong protection but are easier to handle and more cost-effective in transportation.

For Temporary Structures

When building temporary structures like exhibition booths or partitions, flexibility is key. Honeycomb paperboard’s lightweight nature and ease of assembly make it perfect for these applications. It’s easy to transport and assemble, making it ideal for quick setups.

Honeycomb paperboard is a versatile, sustainable, and cost-effective material. It offers strength, lightweight properties, and eco-friendly benefits. Its applications span packaging, construction, and more, showing great potential for future growth.

Choosing honeycomb paperboard brings many advantages. It provides cost savings and reduces environmental impact, making it a smart option for businesses across industries.

Learn more about honeycomb paperboard, request samples, or explore custom solutions to meet your needs.

A: Honeycomb paperboard is made from 100% recycled paper, with a hexagonal core structure sandwiched between two layers of paper.

A: Honeycomb paperboard is used in packaging, construction, automotive, furniture manufacturing, and signage, thanks to its strength, light weight, and eco-friendliness.

A: It is eco-friendly because it is made from recycled materials, biodegradable, non-toxic, and energy-efficient to produce compared to traditional packaging materials.

A: Yes, honeycomb paperboard can be easily cut into various sizes and shapes to meet specific requirements, whether for packaging, construction, or other uses.

A: Honeycomb paperboard is a cost-effective alternative to more expensive materials, offering long-term savings in transportation and reducing packaging costs.