Author: Site Editor Publish Time: 2025-12-31 Origin: Site

Packaging materials play a critical role in ensuring product safety during transport. But how do you choose the best one? Corrugated vs. Honeycomb Cardboard is a key decision for many businesses.

In this article, we’ll explore the differences between these two materials. You’ll understand which one is more suitable for your packaging needs, balancing cost, strength, and sustainability.

Corrugated cardboard is one of the most versatile and widely used packaging materials. It consists of three layers of paper: two outer flat sheets and a wavy, fluted layer in between. The fluted layer, often referred to as the "corrugate," provides rigidity and cushioning, which allows the cardboard to handle compressive forces without buckling.

● Fluted Core: The core's shape and size play a critical role in determining the strength of the cardboard. Flutes can vary in size, providing varying levels of protection depending on the weight and fragility of the items being packaged.

● Flat Linerboards: The two linerboards on either side of the fluted core are typically made from kraft paper. They provide additional protection and make the material more resistant to tearing, puncturing, and moisture damage.

The combination of the fluted core and linerboards offers a balance of strength, flexibility, and lightness, which makes corrugated cardboard an excellent choice for general-purpose packaging.

Corrugated cardboard is known for its moderate strength. While it excels in lightweight applications, it does not provide the same level of durability as other materials, such as honeycomb cardboard, under prolonged stress or heavy loads.

● Compressive Strength: The strength of corrugated cardboard is determined by the thickness of the flutes. Thicker flutes can support more weight, but this also adds to the overall weight of the material.

● Durability: While corrugated cardboard performs well in standard shipping applications, it is susceptible to wear and tear over time. Under conditions of high pressure or long-term storage, the cardboard may lose its shape or compress, resulting in weakened protection.

Example: Corrugated cardboard is commonly used for packaging retail items such as clothing, books, and consumer electronics, which are generally lightweight and do not require heavy-duty protection.

An often overlooked but important consideration for many businesses is the environmental impact of packaging materials. Corrugated cardboard is widely regarded as one of the most eco-friendly options due to its recyclability.

● Recyclable: The vast majority of corrugated cardboard is recyclable, making it an environmentally responsible choice. It can be repurposed into new packaging materials or even used in other industries such as construction.

● Weight Consideration: However, one drawback is the weight. Corrugated cardboard is relatively heavy, which can increase transportation costs. Heavier materials contribute to higher fuel consumption and greater carbon emissions, impacting sustainability efforts.

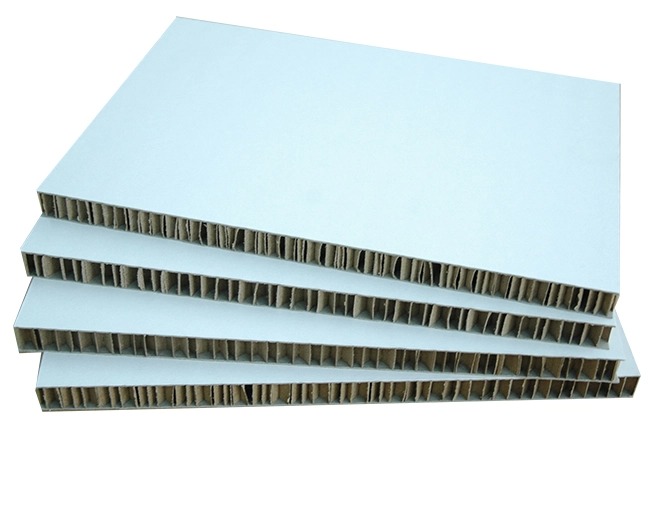

Honeycomb cardboard features a unique design consisting of a honeycomb-shaped core between two flat sheets of paper. This structure offers superior strength while remaining lightweight, making it an excellent choice for heavy-duty applications.

● Hexagonal Cells: The honeycomb structure consists of interlocking hexagonal cells that distribute weight and pressure evenly. This provides exceptional support, even under heavy loads or high stacking pressure.

● Flat Sheets: The outer layers of honeycomb cardboard are made from smooth linerboards, similar to corrugated cardboard. These provide additional strength and durability, making the material suitable for both protection and cushioning.

The key advantage of honeycomb cardboard lies in its ability to maintain its shape and performance under pressure without increasing material thickness or weight.

Honeycomb cardboard is significantly stronger than corrugated cardboard, especially when it comes to compression resistance. The unique structure allows it to withstand higher loads and absorb shock better than corrugated materials.

● Higher Compression Resistance: The honeycomb design distributes force across the entire surface, preventing localized stress points that could cause deformation or failure. This makes honeycomb cardboard ideal for heavy-duty applications such as industrial shipping and long-term storage.

● Shock Absorption: Honeycomb cardboard also excels in shock resistance, offering superior protection for fragile items. Its ability to absorb impact makes it a preferred choice for high-value goods that need extra protection during transit.

Example: Honeycomb cardboard is commonly used for packaging products like automotive parts, electronic devices, and high-end furniture, where both durability and protection are essential.

Like corrugated cardboard, honeycomb cardboard offers environmental benefits due to its recyclability and reduced weight.

● Lighter Weight: The efficient use of material in honeycomb cardboard makes it lighter than corrugated cardboard, leading to lower transportation costs and reduced carbon emissions.

● Reusable: Many honeycomb products are designed to be reused, which can further minimize environmental impact. The long lifespan of honeycomb packaging helps reduce the need for frequent replacements, making it a more sustainable option in the long term.

The main structural difference between corrugated cardboard and honeycomb cardboard is their core design.

● Corrugated Cardboard: Features a fluted core sandwiched between two flat sheets, offering strength in one direction. The fluted layer provides rigidity, but it cannot evenly distribute force across multiple directions.

● Honeycomb Cardboard: The hexagonal cell structure provides strength in multiple directions, making it more resilient under pressure. This design allows honeycomb cardboard to handle greater loads and resist deformation under high compression.

● Corrugated Cardboard: Works well for light to moderate loads. However, under heavy or long-term pressure, corrugated cardboard can compress and lose its structural integrity.

● Honeycomb Cardboard: Its multi-directional strength and compression resistance make it ideal for high-stress environments. It performs better under stacked loads and maintains its strength over extended periods.

● Honeycomb Cardboard: Much lighter than corrugated cardboard, honeycomb cardboard reduces shipping costs and minimizes fuel consumption, contributing to overall cost efficiency.

● Corrugated Cardboard: Heavier than honeycomb cardboard, which can increase transportation costs, especially when shipping in large quantities.

Feature | Corrugated Cardboard | Honeycomb Cardboard |

Core Design | Fluted core between two flat sheets, strength in one direction. | Hexagonal cell structure, strength in multiple directions. |

Strength & Compression | Suitable for light to moderate loads, can compress under pressure. | Superior compression resistance, maintains strength under heavy loads. |

Weight | Heavier, increases shipping costs. | Lighter, reduces shipping costs and fuel consumption. |

Efficiency | Less efficient for heavy shipments. | More efficient, ideal for high-stress, long-term storage. |

When it comes to impact resistance, honeycomb cardboard clearly outperforms corrugated cardboard. The honeycomb design absorbs impact forces more efficiently, protecting fragile items from damage.

● Honeycomb: Absorbs shock and impact from multiple directions, making it ideal for transporting electronics, glass, and other delicate items.

● Corrugated: Although effective for general protection, corrugated cardboard is prone to damage after impact, especially on the edges and corners.

Both materials are susceptible to moisture, but honeycomb cardboard performs better in high-humidity environments.

● Honeycomb: Its structure is more resistant to moisture, which helps maintain its strength even in wet conditions. However, prolonged exposure to moisture can still weaken it over time.

● Corrugated: When exposed to moisture, corrugated cardboard absorbs water, causing it to lose strength and integrity more quickly than honeycomb cardboard.

Honeycomb cardboard offers better thermal insulation properties compared to corrugated cardboard, making it a better choice for temperature-sensitive goods.

● Honeycomb: Provides natural insulation, which helps maintain the temperature of goods during transportation, making it ideal for shipping perishable items like food and pharmaceuticals.

● Corrugated: While it offers basic protection, corrugated cardboard does not provide the same level of thermal insulation as honeycomb.

Condition | Corrugated Cardboard | Honeycomb Cardboard |

Impact Resistance | Prone to damage after impact, especially edges. | Absorbs shock and impact from multiple directions, ideal for fragile items. |

Moisture Sensitivity | Absorbs moisture quickly, losing strength. | More moisture-resistant, maintains strength longer in wet conditions. |

Temperature Sensitivity | Provides basic protection, limited thermal insulation. | Offers natural insulation, ideal for temperature-sensitive shipments. |

Corrugated cardboard is a versatile and cost-effective packaging solution, ideal for shipping and protecting a wide variety of products.

● Retail Packaging: Frequently used for packaging retail products, including clothing, books, and home goods.

● Shipping Cartons: Commonly used for bulk shipping of non-fragile items, such as consumer electronics, which do not require heavy-duty protection.

For businesses that need temporary storage or packaging for lightweight items, corrugated cardboard is a reliable and affordable option.

● Temporary Storage: Ideal for short-term storage of items that are not sensitive to pressure or handling.

● Lower-Impact Environments: Perfect for environments where the packaging will not be subjected to high pressure or long-term compression.

Given its affordability, corrugated cardboard is often the material of choice for high-volume shipping, especially for lower-cost items.

● Bulk Shipping: Great for companies shipping large quantities of products at a low cost per unit.

● Economical: The low cost of production and widespread availability make it an attractive option for businesses seeking to minimize packaging costs.

Use Case | Description | Examples |

General Packaging Solutions | Cost-effective, versatile packaging for various products. | Retail packaging (clothing, books, home goods). |

Short-Term Use & Lower-Impact Environments | Ideal for lightweight items and temporary storage. | Temporary storage, environments with low compression. |

Cost-Effective Solution for Large Quantities | Best for high-volume, budget-conscious shipping. | Bulk shipping, affordable packaging for large volumes. |

For industries that need to ship heavy or fragile goods, honeycomb cardboard offers superior protection.

● Automotive Parts: Ideal for shipping automotive components that require protection against compression and impact.

● Furniture: Protects large, heavy items from damage during transit and handling.

Honeycomb cardboard is the preferred choice for situations where goods are stored for long periods under heavy stacking.

● Warehousing: Provides reliable long-term storage solutions, particularly for products that will be stacked high for extended durations.

● Heavy Loads: Ensures that heavy items remain protected without causing structural collapse or product deformation.

With its superior insulation properties, honeycomb cardboard is perfect for industries that need to maintain product temperatures during shipping.

● Food and Pharmaceuticals: Often used for packaging and shipping perishable items that need to stay within a certain temperature range during transit.

Use Case | Description | Examples |

Heavy-Duty Shipping and Storage | Offers superior protection for heavy or fragile goods. | Automotive parts, furniture. |

Long-Term Storage & High-Pressure Environments | Ideal for goods stored under heavy stacking for long periods. | Warehousing, heavy loads. |

Temperature-Sensitive Shipments | Provides thermal insulation to maintain product temperature. | Food, pharmaceuticals, perishable items. |

Corrugated cardboard is best for lightweight, cost-effective packaging. It suits non-fragile items in low-compression environments but may struggle under heavy loads or long-term use. Honeycomb cardboard excels in heavy-duty applications. It offers superior strength, shock absorption, and long-term durability, making it ideal for industries requiring high performance under pressure.

For budget-conscious, lightweight packaging, corrugated cardboard is a solid choice. However, for heavy-duty or temperature-sensitive products, honeycomb cardboard from Wuxi Shenxi Honeycomb Machinery Factory provides unmatched protection and cost efficiency.

A: Corrugated vs. honeycomb cardboard differs in structure. Corrugated cardboard has a fluted core between two flat sheets, providing strength in one direction. Honeycomb cardboard uses a hexagonal cell design, offering multi-directional strength and better resistance to compression, ideal for heavy-duty applications.

A: Corrugated vs. honeycomb cardboard depends on the need. Use corrugated for lightweight, cost-effective packaging of non-fragile items. Honeycomb is better for heavy-duty shipping, offering more protection for fragile or high-value goods, especially under pressure or long-term storage.

A: Honeycomb cardboard is stronger due to its hexagonal cell structure, which distributes pressure evenly across multiple directions. This provides superior compression resistance and shock absorption, making it ideal for heavy-duty applications. Corrugated cardboard, with its fluted layer, provides strength only in one direction.

A: Honeycomb cardboard is lighter than corrugated, reducing transportation costs and carbon emissions. It is often reusable, which lowers waste. While corrugated cardboard is recyclable, its higher weight leads to more fuel consumption during transport, making honeycomb a more sustainable choice in the long run.

A: Honeycomb vs. corrugated cardboard pricing depends on use. Corrugated cardboard is cheaper and works for light-duty applications. However, honeycomb, though more expensive, offers superior protection, making it more cost-effective for industries needing high durability, long-term storage, or protection for fragile items.

A: Honeycomb cardboard is ideal for heavy-duty packaging and shipping, such as furniture, automotive parts, and electronics. Its shock absorption and compression resistance make it perfect for fragile, high-value items that need extra protection during transit or long-term storage.