Author: Site Editor Publish Time: 2025-11-24 Origin: Site

In the world of modern materials, the comparison between aluminum honeycomb panels and solid aluminum sheets is a frequent point of discussion. Both materials are valued for their properties, yet they serve distinctly different functions and offer unique advantages.

Solid aluminum is a well-understood, versatile metal known for its strength and malleability. It has been a reliable choice for decades across countless industries. In contrast, aluminum honeycomb panels represent a more advanced, composite approach. By sandwiching a hexagonal core between two thin aluminum sheets, these panels achieve remarkable structural efficiency.

This guide will provide a complete performance comparison between these two materials. We will analyze their differences across key metrics like strength-to-weight ratio, cost, durability, and thermal performance. Whether you are designing facades, ceiling systems, transportation components, or industrial machinery, understanding the nuances of aluminum honeycomb panels vs. solid aluminum will help you make an informed decision for your next project.

Table of Contents

1. What Are Aluminum Honeycomb Panels?

2. What Is Solid Aluminum?

3. Aluminum Honeycomb Panels vs. Solid Aluminum: Side-by-Side Performance Comparison

4. Application-by-Application Comparison

5. Pros and Cons Summary Table

6. How to Choose Between Honeycomb Panels and Solid Aluminum

7. Frequently Asked Questions

8. Making the Right Choice

Aluminum honeycomb panels are composite sandwich panels inspired by the natural strength and efficiency of a bee’s honeycomb. They consist of a core made of thin aluminum foil shaped into a hexagonal cellular structure, which is then bonded between two outer aluminum face sheets. This design creates a lightweight yet incredibly rigid and strong material.

The genius of the honeycomb panel lies in its core. The hexagonal cells are arranged so that the solid material makes up only a small fraction of the panel’s volume. This cellular structure dramatically reduces weight while creating a system that can withstand significant compressive and shear forces. When a load is applied, the force is distributed across the entire panel, preventing localized deformation and maintaining structural integrity. This concept allows the panel to achieve a high level of rigidity without the mass of a solid material.

The manufacturing process involves three primary components: two aluminum face sheets and the aluminum honeycomb core.

The honeycomb core is first formed by bonding and expanding layers of aluminum foil.

A layer of adhesive is applied to both the top and bottom of the core.

The face sheets are then placed on either side of the adhesive-coated core.

The entire assembly is placed in a press under heat and pressure, which cures the adhesive and creates a permanent bond between the core and the face sheets, forming a single, integrated panel.

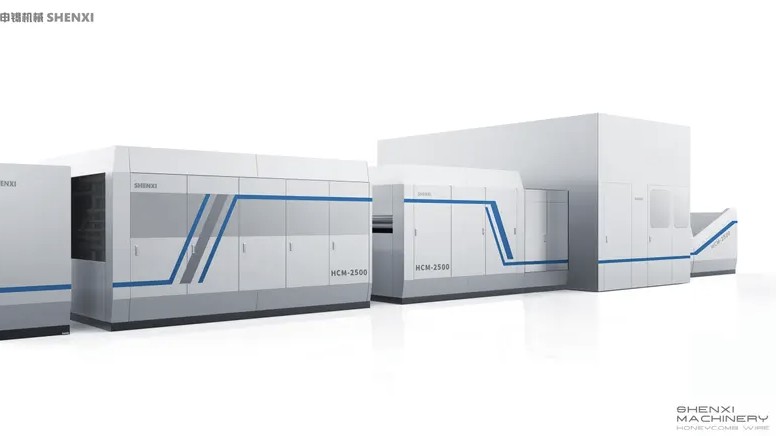

Learn more about Honeycomb Panels machine

The unique construction of aluminum honeycomb panels gives them several distinct properties:

Load Distribution: The honeycomb core evenly distributes stress across the panel surface, enhancing its ability to handle loads without bending or breaking.

Deformation Resistance: The high stiffness-to-weight ratio makes these panels highly resistant to denting, warping, and bending under pressure.

Thermal Insulation: The air trapped within the honeycomb cells acts as a natural insulator, slowing the transfer of heat and helping to maintain stable indoor temperatures.

Sound Dampening: The cellular structure also helps to absorb sound waves and dampen vibrations, making it an excellent choice for environments where noise control is important.

Corrosion Resistance: The aluminum face sheets are naturally corrosion-resistant and are often treated with protective coatings to enhance durability, especially in outdoor or marine environments.

Thanks to their lightweight and high-strength characteristics, aluminum honeycomb panels are used in a wide range of demanding applications:

Architectural ceilings and large-format facades

Aircraft interiors, including floors, partitions, and galleys

Rail car interiors and doors

Lightweight partitions and cleanroom walls

Marine vessels for bulkheads, decks, and interior joinery

Automotive components and vehicle structures

Solid aluminum is a single-layer metal sheet or plate made from aluminum alloy. Unlike honeycomb panels, it is not a composite or sandwich structure. It is a homogenous material known for its lightweight nature (relative to steel), strength, and excellent formability. It is abundant and widely used in countless industrial and commercial applications due to its favorable properties.

A solid aluminum sheet is exactly what its name implies: a uniform, solid piece of metal. Its thickness is consistent throughout, and it has no internal core or layered construction. Its strength and rigidity are directly proportional to its thickness and the specific alloy used.

Solid aluminum is defined by a set of well-known and reliable properties:

Lightweight Metal: While heavier than a honeycomb panel of the same thickness, it is significantly lighter than steel, making it a popular choice where weight reduction is a goal.

High Corrosion Resistance: Aluminum naturally forms a protective oxide layer that resists corrosion, a key advantage for outdoor and marine applications.

High Thermal and Electrical Conductivity: Unlike honeycomb panels, solid aluminum is an excellent conductor of heat and electricity.

Excellent Formability and Machinability: solid aluminum is easy to cut, bend, drill, and weld. It can be machined at high speeds without creating sparks and allows for long tool life, making it ideal for fabrication-heavy projects.

The versatility of solid aluminum makes it a go-to material across numerous sectors:

Building construction for windows, doors, and structural framing

Transportation for car bodies, bicycle frames, and aircraft parts

Packaging for beverage cans and foil

General fabrication for industrial components and machine parts

Consumer electronics and kitchen utensils

To make the best choice, it’s essential to compare these materials across a range of performance metrics.

| Performance Metric | Aluminum Honeycomb Panels | Solid Aluminum |

|---|---|---|

| Weight | ⭐ Extremely lightweight (10 mm ≈ 5.2 kg/m²) | Heavier (3 mm ≈ 8.16 kg/m²) |

| Strength & Stiffness | ⭐ Very high stiffness-to-weight ratio (I-beam effect) | Requires much greater thickness to achieve similar stiffness |

| Deformation Resistance | ⭐ Highly resistant to denting, warping, local stress | More prone to denting and thermal warping |

| Thermal Performance | ⭐ Built-in insulation from air-filled core | High thermal conductivity; transfers heat quickly |

| Acoustic Performance | ⭐ Good sound and vibration dampening | Transmits sound and vibrations easily |

| Corrosion Resistance | Excellent; treated face sheets | Naturally corrosion-resistant |

| Outdoor Durability | ⭐ Superior flatness and dimensional stability | Large sheets may show oil-canning (visible distortion) |

| Fire Performance | Non-combustible; slows heat transfer | Non-combustible |

| Machinability | Requires specialized cutting/edge tooling | ⭐ Easy to cut, bend, drill, weld |

| Cost | Higher manufacturing cost | ⭐ More economical overall |

| Installation Load | ⭐ Very low dead load; lighter support structure | Heavier; requires stronger, more expensive support |

Aluminum honeycomb panels are drastically lighter than solid aluminum. A 10mm thick honeycomb panel can weigh as little as 5.2 kg/m², while a 3mm solid aluminum panel weighs around 8.16 kg/m², according to data from Nexcomb. The hollow cells of the honeycomb core reduce the total mass by up to 90% compared to a solid piece of the same dimensions, without sacrificing rigidity. This weight reduction means less strain on building structures and easier installation.

When it comes to structural efficiency, honeycomb panels have a far superior stiffness-to-weight ratio. The sandwich structure acts like an I-beam, with the face sheets resisting bending forces while the core resists shear forces. This allows a lightweight honeycomb panel to have the same stiffness as a much thicker and heavier solid aluminum plate. Solid aluminum is strong, but to achieve high stiffness, its thickness—and therefore its weight—must be significantly increased.

Honeycomb panels distribute loads across a large surface area, making them highly resistant to deformation, denting, and warping under localized stress. Solid aluminum is more susceptible to denting on impact and can warp under thermal stress, especially in large, thin sheets.

Aluminum honeycomb panels offer built-in thermal insulation. The air trapped within the core’s cells acts as a barrier to heat transfer. In contrast, solid aluminum is a highly effective thermal conductor, meaning it readily transfers heat and cold. This makes honeycomb a better choice for facades and roofs where energy efficiency is a priority.

The cellular structure of honeycomb panels is effective at dampening sound and vibrations. This makes them ideal for creating quieter interior spaces in transportation and architecture. Solid aluminum tends to transmit vibrations and sound with little resistance.

Both materials are highly resistant to corrosion. The aluminum alloys used are naturally rust-proof. Honeycomb panels use treated face sheets for added protection, making them equally suitable for harsh environments.

Both are excellent for exterior use. However, honeycomb panels offer superior flatness and dimensional stability over large surfaces, especially when exposed to temperature fluctuations. Large solid aluminum sheets can be prone to “oil canning,” or visible warping, which is not an issue with rigid honeycomb panels.

Aluminum is a non-combustible material. Both solid aluminum and honeycomb panels perform well in fire tests. The structure of honeycomb panels can even enhance heat resistance by slowing the transfer of thermal energy.

Solid aluminum is generally easier to fabricate. It can be cut, drilled, bent, and welded using standard metalworking techniques. Honeycomb panels require specialized tools and processes for cutting and edge finishing to avoid crushing the core. Welding is also not a standard option for honeycomb panels.

Aluminum honeycomb panels typically have a higher upfront production cost due to their complex manufacturing process. However, their lightweight nature can lead to savings in transportation, structural support systems, and installation labor. Solid aluminum is more economical for general-purpose applications and projects with lower structural demands.

The lightweight nature of honeycomb panels significantly reduces the dead load on a building’s structure, allowing for lighter, less expensive support systems. Solid aluminum panels, being heavier, require a more robust and costly support structure, especially for large facade applications.

The best choice often depends on the specific use case.

For facades, honeycomb panels are often preferred for their lightweight nature, exceptional flatness, and thermal stability. They allow for large, seamless panels without the risk of warping. Solid aluminum is also used but may be limited to smaller panel sizes or require thicker, heavier sheets to maintain flatness.

Honeycomb panels are ideal for large, suspended ceiling systems. Their low weight reduces the load on the overhead structure, and they can span long distances without sagging.

In aviation, rail, and marine industries, weight reduction is critical for fuel efficiency. Honeycomb panels are the go-to material for interior panels, floors, partitions, and doors. Solid aluminum is still used for structural components where its strength and machinability are needed.

For projects that require extensive machining, welding, or forming, solid aluminum is the clear winner. It is perfect for creating machine parts, enclosures, and structural frames. Honeycomb panels are used in industrial settings for lightweight, stiff work surfaces or platforms.

| Aluminum Honeycomb Panels | Solid Aluminum | |

|---|---|---|

| Advantages | - Extremely high stiffness-to-weight ratio - Lightweight and easy to handle - Excellent flatness and deformation resistance - Good thermal and acoustic insulation - Non-combustible | - High strength and durability - Excellent formability and machinability - Lower material cost - Easily welded and fabricated - High corrosion resistance |

| Disadvantages | - Higher initial material cost - Requires specialized fabrication techniques - Cannot be welded - Susceptible to core damage from localized impact | - Heavier than honeycomb panels - Lower stiffness-to-weight ratio - Prone to warping (“oil canning”) in large sheets - Poor thermal and acoustic insulator |

Your decision should be guided by the specific demands of your project.

Choose aluminum honeycomb panels if your project requires:

Extreme lightweighting: Essential for aerospace, marine, and high-performance transportation.

High stiffness over large spans: Ideal for large, flat architectural facades, ceilings, and partitions.

Thermal or acoustic insulation: When energy efficiency or noise reduction is a key design goal.

Opt for solid aluminum when your project involves:

Complex shapes and high machining demands: If you need to bend, weld, or drill the material extensively.

High-impact environments: Where the material must withstand direct, forceful impacts without core damage.

A lower initial budget: For general-purpose applications where the benefits of a honeycomb structure do not justify the added cost.

Ask yourself these four questions:

Strength & Stiffness: Is a high stiffness-to-weight ratio critical, or is raw strength sufficient?

Weight: Is minimizing weight a primary objective for performance or installation?

Budget: What is the balance between upfront material costs and potential long-term savings on structure and installation?

Processing Needs: Does the design require complex fabrication like welding or forming?

In terms of stiffness-to-weight ratio, honeycomb panels are significantly “stronger.” A lightweight honeycomb panel can provide the same rigidity as a much heavier solid aluminum sheet. However, for raw tensile or impact strength, a thick solid aluminum plate will be more robust.

When manufactured correctly with proper surface treatment and high-quality adhesives, honeycomb panels are highly resistant to corrosion and delamination. They are designed to withstand harsh weather conditions and are widely used in marine and exterior applications.

Yes. With treated aluminum face sheets and sealed edges, they are an excellent choice for outdoor applications like building facades, offering superior flatness and durability compared to other materials.

The required thickness depends on the panel size, load requirements, and desired flatness. For facades, solid aluminum sheets are often 3mm or thicker to prevent warping, which adds significant weight. An engineer should always perform calculations for structural applications.

It depends on the application. If weight reduction leads to significant savings in structural support, transportation, and installation, or if superior flatness and thermal performance are required, then honeycomb panels often provide a better return on investment.

Ultimately, neither material is universally superior; the “better” choice is entirely dependent on the application. Solid aluminum remains an indispensable, economical material for projects where machinability and raw strength are paramount. It is a proven workhorse in countless industries.

However, aluminum honeycomb panels represent the pinnacle of structural efficiency. For modern architecture, transportation, and any application where performance must be maximized and weight minimized, they are often the ideal solution. As technology advances and architects push the boundaries of design with larger, lighter, and more energy-efficient structures, the trend toward advanced composite systems like aluminum honeycomb panels will only continue to grow. By carefully weighing the performance factors discussed, you can confidently select the material that will bring your vision to life.