Author: Site Editor Publish Time: 2025-10-19 Origin: Site

Honeycomb cardboard panels are a revolutionary material, widely regarded for their sustainability, strength, and versatility. As industries strive for eco-friendly alternatives, honeycomb cardboard has emerged as a game-changer across various applications. From packaging and construction to furniture design, these panels have found applications in numerous sectors due to their lightweight yet durable nature. In this article, we will explore the diverse uses of honeycomb cardboard panels and the compelling benefits they offer, demonstrating why they are becoming the preferred choice for both manufacturers and consumers.

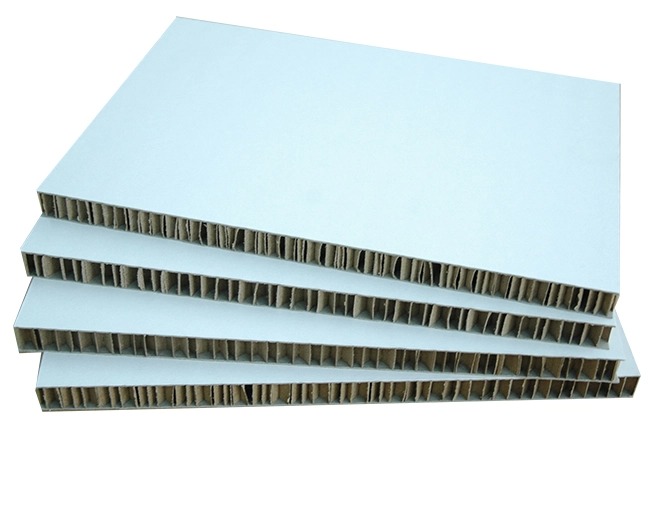

Honeycomb cardboard panels are made by sandwiching a honeycomb-shaped core between two flat sheets of cardboard or paperboard. This structure provides exceptional strength-to-weight ratio, making them ideal for applications that require both durability and lightweight properties. The core is typically made from recycled paper or cardboard, enhancing the eco-friendliness of the material. The outer layers are often treated or laminated to provide additional protection and improve the overall performance of the panel.

The unique honeycomb structure offers numerous benefits, including increased load-bearing capacity, thermal insulation, and resistance to impact, making it a versatile material suitable for a wide range of applications.

Honeycomb cardboard panels are most commonly used in packaging, where their lightweight yet robust design makes them ideal for protecting fragile goods during shipping and transportation. They are often used in custom-sized boxes, pallets, and protective inserts to ensure that products remain secure during transit.

The honeycomb structure acts as a shock absorber, providing a cushion for sensitive items, such as electronics, glassware, and fragile parts. Their use in packaging helps to reduce material waste since they are made from recyclable paperboard, aligning with global sustainability trends.

| Type of Packaging | Benefits | Common Uses |

|---|---|---|

| Protective Inserts | Lightweight and durable shock absorption | Electronics, Glass Items |

| Shipping Boxes | Cost-effective and eco-friendly | E-commerce, Heavy Goods |

| Pallets | Strong load-bearing capacity and eco-friendly | Industrial and Retail Goods |

The construction industry has seen the rise of honeycomb cardboard panels as a sustainable alternative to traditional building materials such as plywood, MDF, and plastic composites. These panels are used for creating lightweight partition walls, floors, and even doors. Their high strength-to-weight ratio makes them particularly useful in modular construction, where ease of transport and assembly is key.

Honeycomb cardboard panels also offer excellent thermal insulation properties, helping to improve energy efficiency in buildings. Additionally, since they are made from recycled materials, their use reduces the overall carbon footprint of construction projects, contributing to environmentally conscious building practices.

| Construction Application | Benefits | Common Uses |

|---|---|---|

| Partition Walls | Easy to install, lightweight, eco-friendly | Office and Residential Dividers |

| Floors and Ceiling Panels | Soundproofing, heat insulation | Temporary Structures, Hotels |

| Modular Homes | Cost-effective, quick assembly | Prefabricated Homes, Pop-up Stores |

Honeycomb cardboard panels are increasingly being used in the furniture industry, offering an innovative approach to creating functional and aesthetically pleasing designs. These panels are not only strong and durable but also provide a sleek, modern look with their smooth surface. Due to their light weight, furniture made from honeycomb cardboard is easy to move and transport, making it a popular choice for both home and office environments.

The honeycomb core ensures that the furniture remains sturdy despite its lightness, while the recyclable nature of the material appeals to eco-conscious consumers looking for sustainable options. Items such as tables, chairs, shelving units, and even couches have been created using honeycomb cardboard, offering an alternative to heavier and less sustainable materials.

| Furniture Type | Benefits | Common Uses |

|---|---|---|

| Chairs and Tables | Lightweight, strong, and eco-friendly | Offices, Homes, Events |

| Shelving Units | Easy to assemble, modern design | Living Rooms, Offices |

| Modular Furniture Systems | Cost-effective, space-efficient | Dorm Rooms, Small Apartments |

The automotive industry has embraced honeycomb cardboard panels for their use in lightweight vehicle construction. These panels are utilized in car interiors, such as for dashboards, door panels, and seats. The lightweight nature of honeycomb cardboard helps to reduce the overall weight of the vehicle, improving fuel efficiency without compromising safety or aesthetics.

Honeycomb cardboard also has soundproofing properties, which contribute to reducing road noise, providing a more comfortable driving experience. The material’s ability to absorb impact helps improve safety features in vehicles, especially in the event of a collision.

| Automotive Application | Benefits | Common Uses |

|---|---|---|

| Interior Panels | Lightweight, impact-resistant | Door Panels, Dashboards |

| Sound Insulation | Noise reduction, eco-friendly | Floor Mats, Upholstery |

| Structural Components | Enhances safety, reduces weight | Car Seats, Trunks |

In the aerospace industry, every gram counts. Honeycomb cardboard panels are increasingly used in the construction of aircraft components where weight reduction is crucial. They are used for creating interior panels, partitions, and even in some structural components, where their strength-to-weight ratio is highly valued.

The material helps to reduce the overall weight of aircraft, leading to fuel savings and improved performance. Additionally, honeycomb cardboard’s thermal and acoustic insulation properties contribute to a more comfortable cabin environment for passengers.

| Aerospace Application | Benefits | Common Uses |

|---|---|---|

| Interior Panels | Lightweight, soundproofing, heat insulation | Cabin Walls, Partitions |

| Structural Components | Reduces weight, maintains structural integrity | Aircraft Doors, Floors |

| Cargo Containers | Durability, impact resistance | Airplane Cargo Hold |

One of the most significant advantages of honeycomb cardboard panels is their eco-friendliness. Made primarily from recycled paper and cardboard, these panels offer a sustainable alternative to traditional materials like plastic and wood. They are fully recyclable, and using them in various industries helps reduce overall environmental impact.

Despite their lightweight design, honeycomb cardboard panels are exceptionally strong. The honeycomb structure maximizes strength while minimizing the amount of material needed. This strength makes them ideal for use in packaging, construction, and transportation, where durability is essential.

Honeycomb cardboard panels are an affordable solution, especially for industries looking to cut costs on material and transportation. Their light weight reduces shipping costs, and their recyclability lowers disposal costs, making them a cost-effective choice in the long term.

Honeycomb cardboard can be customized to meet the specific needs of different industries. Whether for packaging, construction, or furniture, these panels can be made in various sizes, thicknesses, and strengths to suit different applications.

The unique honeycomb structure provides excellent thermal and sound insulation properties, which is highly beneficial in industries like construction, automotive, and aerospace. These panels help maintain comfortable temperature levels and reduce noise, enhancing overall user experience.

Honeycomb cardboard panels have revolutionized industries across the board, offering a sustainable, cost-effective, and durable alternative to traditional materials. From packaging and construction to furniture and aerospace, their applications are vast, and the benefits are undeniable. As the world continues to move towards more environmentally conscious practices, honeycomb cardboard panels are positioned to play an increasingly important role in shaping the future of manufacturing, packaging, and design.

1. What are honeycomb cardboard panels made of?

Honeycomb cardboard panels are made by sandwiching a honeycomb-shaped core between two layers of cardboard or paperboard. The core is typically made from recycled paper or cardboard, making the material eco-friendly.

2. How strong are honeycomb cardboard panels?

Despite being lightweight, honeycomb cardboard panels are incredibly strong. The honeycomb structure maximizes strength while minimizing the amount of material used, making them ideal for various applications requiring durability.

3. Are honeycomb cardboard panels recyclable?

Yes, honeycomb cardboard panels are made from recyclable materials and are fully recyclable themselves, making them an environmentally friendly option for various industries.

4. Can honeycomb cardboard panels be used in construction?

Yes, honeycomb cardboard panels are increasingly used in the construction industry for partition walls, flooring, and even modular homes due to their lightweight and durable properties.

5. How do honeycomb cardboard panels help in the automotive industry?

In the automotive industry, honeycomb cardboard panels are used for interior components, such as dashboards and door panels. They reduce the overall weight of the vehicle, improving fuel efficiency, and offer soundproofing benefits.